Transport systems

for sensitive substrates

Safe transport of sensitive workpieces, developed specifically for the system, supplied ready for installation.

It's good when everything runs smoothly. Not just the processes, but also the substrate transport and the transfer between the process steps. If there's a problem there, we'll find the right transport system for you. We've already developed many designs for picking up substrates, substrate carriers or workpiece carriers precisely at point A and putting them down at point B. Sometimes even completely contact-free, such as with a contactless magnetic levitation system.

Functional precision parts and components that we manufacture in large quantities with the required tolerances – our recipe for success since 1986. From this we build the transport system with which every transfer will run in your system collision-free, smoothly, quietly, and without damage.

Your benefits

Every project and every carrier in the best hands- Custom development – construction of substrate carriers according to your specifications

- Manufacturing expertise – including processing of very large carriers

- Industry know-how – Experience with carriers of different sizes from various industries

- Rapid project progress – design and manufacture of suitable transport systems from a single source

So that from start to stop everything runs precisely

Moving catalog of rollers, conveyor lines and workpiece carriers

Save yourself unnecessary coordination expense Choose a partner who reliably manufactures your transport systems and associated workpiece carriers. This will solve all your transport tasks in vacuum and coating systems.

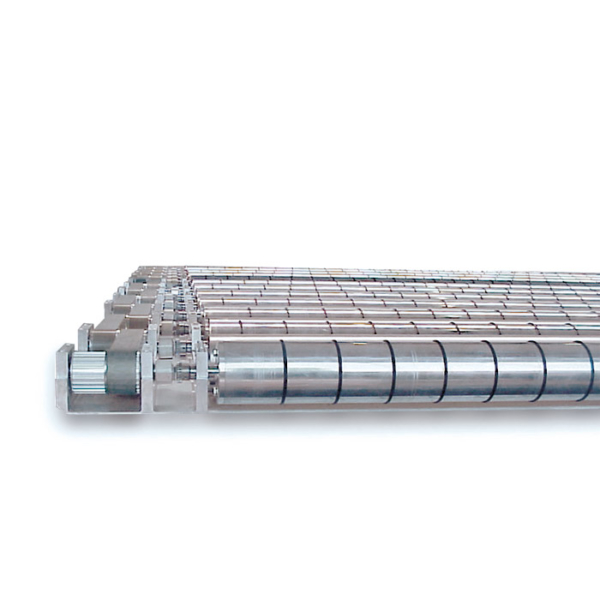

- Transport rollers – Very precisely balanced, with specific geometries and very smooth running; perfect for functions such as separating, translational movements, axial rotations or point loads

- Drive and conveyor lines – for the direct transport of substrates inside and outside the vacuum; ideal for architectural glass, bulletproof glass, glasses for thin-film PV systems and all sensitive substrates

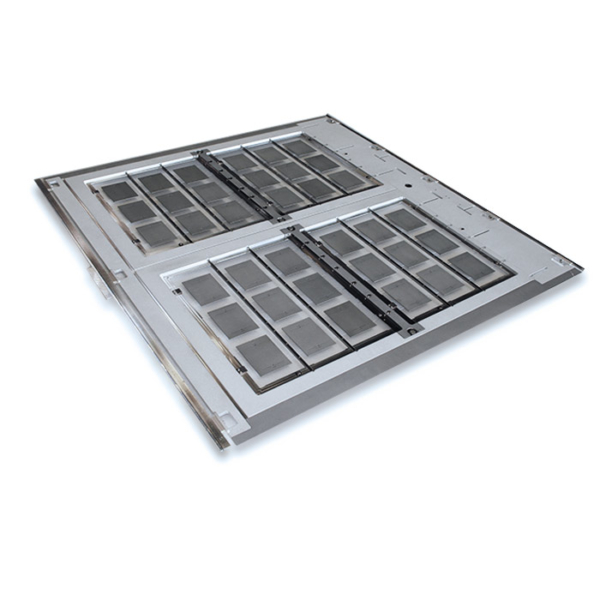

- Workpiece carriers and workpiece carrier systems– developed and manufactured depending on the process and specifically for the substrate, workpiece carriers from 300 x 300 mm up to 2500 mm width, e.g. for displays or panels for PV systems