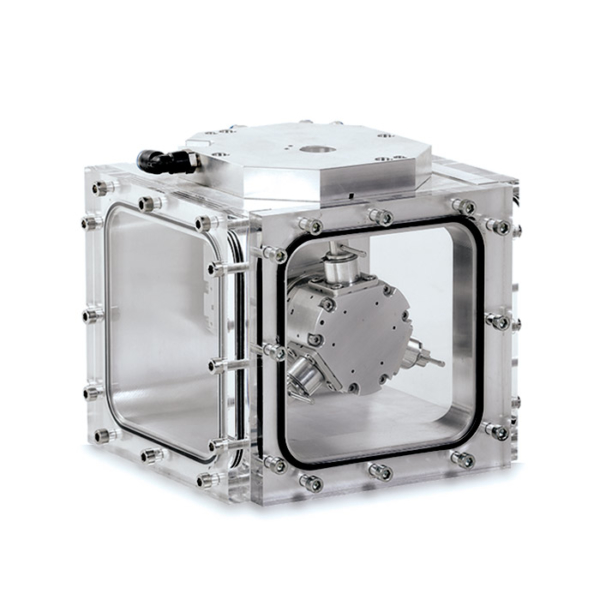

Chambers

for processes and conditioning

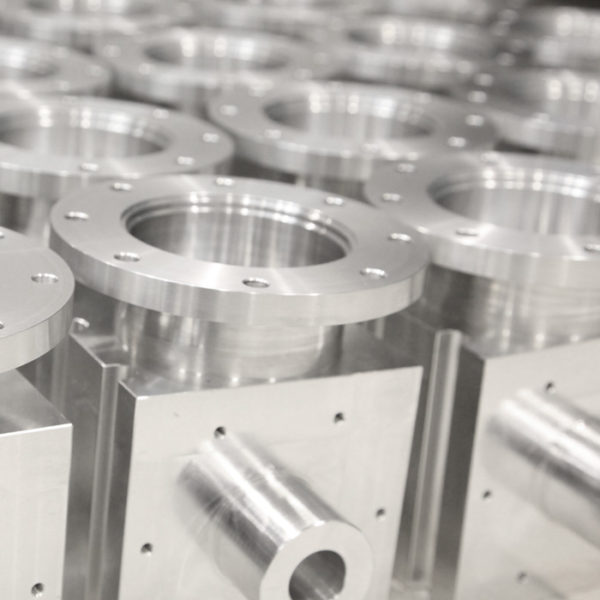

High-precision manufacturing for the secure sealing of sensitive processes

Recipients are functionally sensitive sub-systems. These have to be viewed as a whole. If you pay attention only to airlock flaps, there's a risk of forgetting the details of the sealing surfaces. Or of ignoring the fact that the process chamber has to be readily accessible for maintenance.

To find the solution, you have to look at the whole picture. For example, for sensitive processes we recommend a full metal construction. This is safer and more precise than welded constructions. Engineering, components for airlocks or substrate transfer, design of sealing surfaces, production, pre-assembly – we don't just look at the big picture, we create it.

Think inside the box!

Your benefits

For 30 years, and up to 15 cubic meters- Customized – design tailored to your specifications

- From small to very large – 5000 x 3000 x 1000 mm

- Experience – we've been making vacuum seals for 30 years

- Milled from a solid piece – robust and tight

Everything for vacuum chambers From engineering to leak testing

The best options for your systems

There are many options in the design and construction of vacuum chambers.

And the options don't all meet the challenges equally well. For example: should the airlock be activated pneumatically, electrically or mechanically? Or do you want to combine opening, closing, locking and unlocking in one drive? In that case, a cam gearing would be ideal. It's complex to calculate and challenging to manufacture. But its reliability is unbeatable, and it always operates with high precision.

Questions like these are project-specific. WASSERMANN answers them in collaboration with you, and gets the optimal results from the available options.