Components and assemblies

for vacuum and coating systems

We take care of the critical points

In vacuum technology and coating technology, the cycles of innovation are fast.

Short product life cycles of 3 years are not uncommon, and the requirements for product and process safety are challenging.

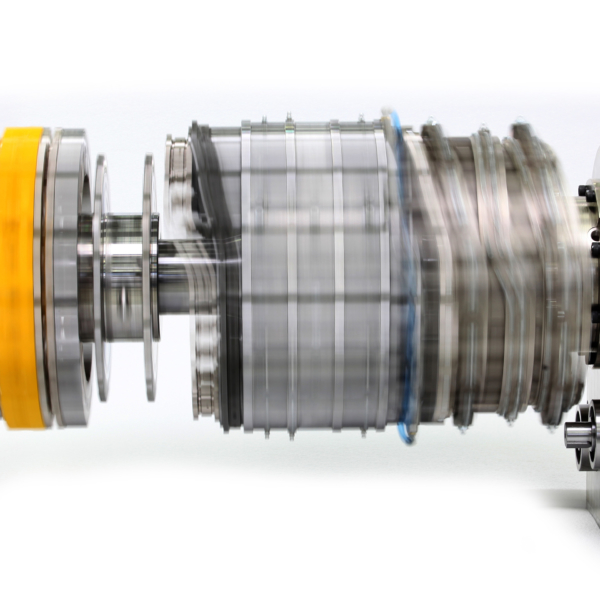

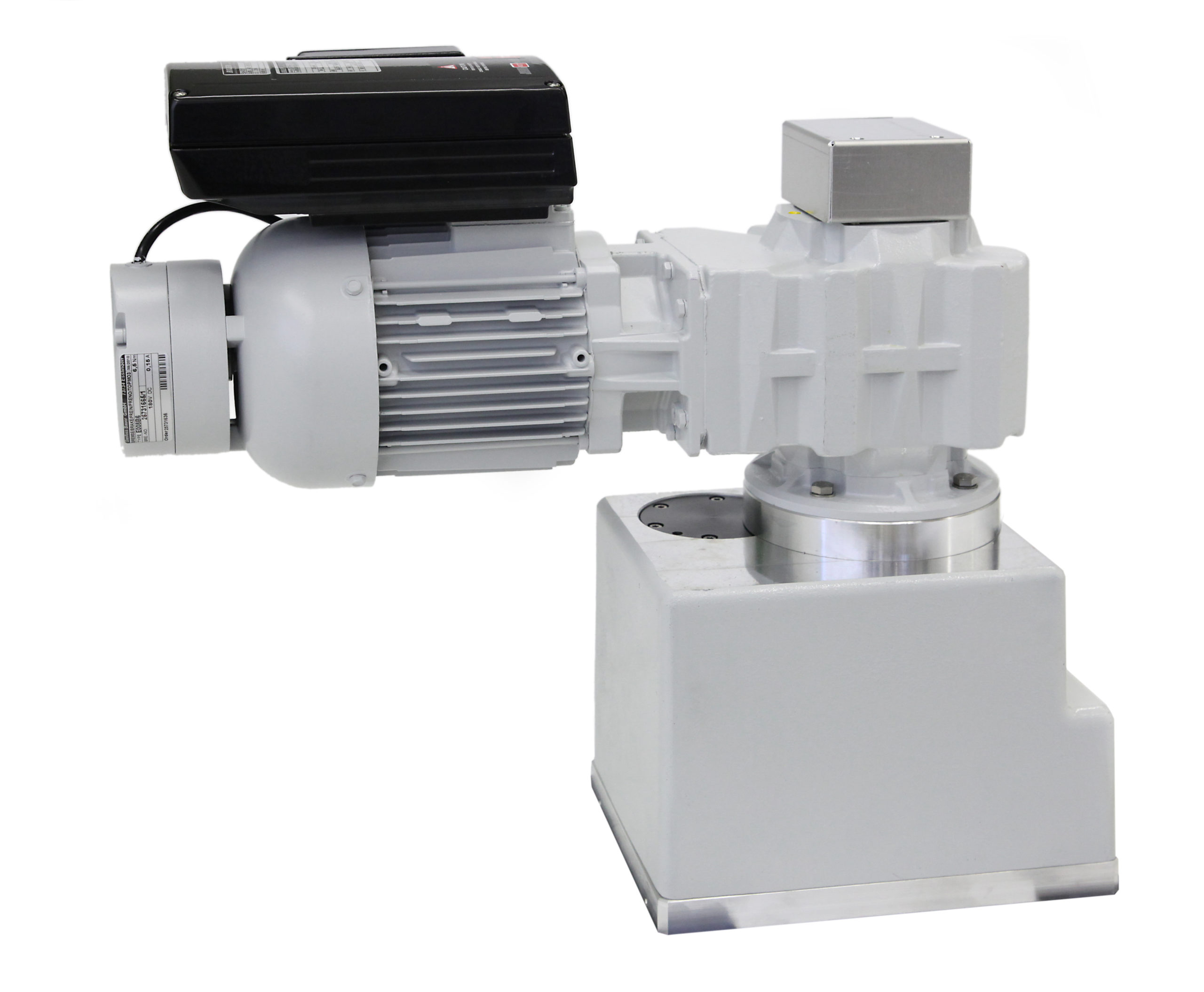

Our components and assemblies are installed in the most up-to-date systems for plasma coating processes. In coating systems, vacuum systems, and systems for thin-film technologies such as sputtering.

When Moore's Law sets the pace of your development, we'll always be there to help you keep up.

Your benefits

at WASSERMANN

- Experienced – partnering with the vacuum industry for over 20 years

- Specific – we implement processes according to your requirements

- Fast – we can handle even large projects at short notice

- Innovative – ready to work together on innovation and make targeted investments

With WASSERMANN, the processes in your systems will run reliably and precisely through future cycles of innovation

Chambers, components, and concepts

Technologies for vacuum and coating systems

Reliable and precise

Components and assemblies

Our know-how

for your products

- as a build-to-print partner for production and assembly

- for optimizing existing solutions

- for further developing systems and their parts

Competitiveness is a team project.

We're your partner.

High speed, high safety

The market for thin-film coatings is growing rapidly, and requires additional production capacity.

Staying abreast of this means being able to develop better processes quickly. WASSERMANN supports you in this high-speed race of high-tech developments, as your supplier of process-critical parts and components. When Moore's Law sets the pace for your development, we'll always be there to help you keep up.

We're your experienced project partner. We act flexibly, plan precisely, and are adept at project management for very large projects.

Precisely because the pace is fast, we pay close attention to the safety of our processes. That applies to our components and assemblies, to our handling of your intellectual property, and to our supply capability. When we make prototypes, we take note of the challenges in making series parts and tell you about them immediately. You can count on WASSERMANN.

Our project mode: All in.

We understand what's important for processes in systems for industrial vacuum and coating technology, including the semiconductor industry and lithography systems. We're your partner, offering valuable benefits and the highest level of engagement in every project phase – because we want to work with you to stay competitive.

Here are just some of your benefits:

- Reliable series manufacturer: We continuously optimize our manufacturing and production methods, as well as the design of your assemblies and components as needed.

- Professional project and time management: We coordinate with you on an ongoing basis, guarantee transparent order tracking, and keep you informed about project progress

- Recognizing design alternatives: Thanks to our experience, we can quickly check other solution options and, if they fit, incorporate them into the current series upon approval

- Assembly processes at a glance: We always take the installation of complex assemblies into account, and as needed develop assembly devices and instructions for assembly at the customer's location and in our own assembly department.

- High degree of automation: Our production is highly automated, so we are well prepared for volatility and movement in the labor market.

- Risk awareness: It's always a good idea to think about the potential risks ahead of time. We use well-founded FMEA-based risk analysis and assessment.

We promise excellent quality – because we test what we make.

At WASSERMANN, quality is a matter of professional pride.

We want the best. So we not only manufacture with reliable accuracy, but we also check our results with excellent measuring and test equipment.

We carefully check that components and assemblies are free from contamination, particularly by metals and non-ferrous metals, silicone-free lubricants, and cleaning agents. We also test for leaks and safety factors such as safety against electrical breakdown.

We set up customer-specific processes for your project based on your factory standards.

Because quality is the top priority for everyone on the WASSERMANN team.

A proactive approach to the future

We don't just wait to see what happens – we actively shape the future.

We're getting ready now for more projects, more production, and even more service.

Through continuous investment in production capacities, buildings, and business equipment, we're keeping pace with rapidly growing markets.

For example, we're about to build a new hall, including a clean room. More space for cleaning, assembling, and packing critical components and assemblies.

All built by us – for thin air, high temperatures, the cleanest rooms, and sensitive substrates.

No example projects have yet been published. Please contact us directly for more information.