Building assemblies

The project assembly of assemblies

opens up space for your business

So you can concentrate on the central questions of your business.

Project plan, parts logistics, assembly, delivery – the project assembly of assemblies is complex. With WASSERMANN, your assemblies will be ready for final assembly at your site on time. We handle all the processes for you. We procure and coordinate the parts, keep standard parts in stock, create the parts lists for assembly and organize the internal processes.

Trend towards complete systems

Switch to ready-to-install complete systems for procurement. You'll reduce procurement costs and the need for coordination. The systems take the strain off incoming goods, warehousing, and logistics. You can even transfer responsibility for quality assurance to a partner. Concentrate on the processes that are important for your company: Development, innovation, service and final assembly of your machines and systems.

With WASSERMANN, you can reliably make this strategic change in procurement.

Your benefits

through the series assembly of assemblies.- High flexibility – we create the space for your project assembly

- Take the pressure off your project – outsource the time-consuming tasks to a partner who understands what you need

- Ready for final assembly – we deliver your assemblies ready for installation and on time

Ideally prepared for production of machines and systems

You start with the final assembly

What you receive from us has already been tested and can be installed immediately. You don't have to waste time with a time-consuming incoming goods inspection. If possible, we test parts in complete assemblies, for example vacuum components.

We are happy to be involved in the design process, but we also do assembly completely independently of it.

There will be close coordination with you on every project. The dialog between partners is indispensable, especially for series launches.

Be flexible, stay flexible

We have flexible areas for the assembly of machines, systems and production lines

One of our strengths is flexibility. There is no substitute for project business. We are able to set up project areas in a short time to realize your assemblies. We assemble machines, turnkey systems and complete production lines. At the end of the project, we transform the project area into a new assembly area.

We're also flexible when it comes to the dimensions. And the weight? There's room for flexibility there too. Our indoor crane moves up to 10 tons through the space.

Before we start assembly, we clean all the parts meticulously. For correctly assembled and functionally flawless assemblies, you have to start with clean parts: that's something we've learned in our 40 years of assembly experience.

WASSERMANN supplies you with large and small piece quantities. Everything from small batches to large series is possible. For individual items or very small series, though, we'll refer you to partners.

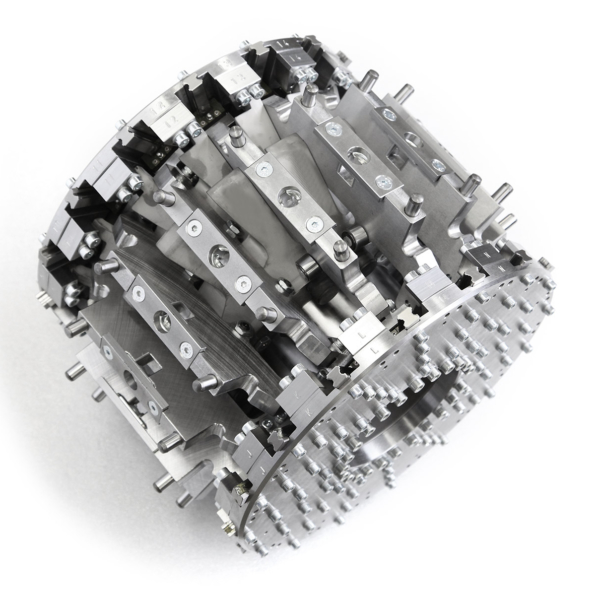

The range of products we do project assembly for extends from transport systems to gearboxes for trimming machines.

We do some things a little differently: better, that is

When it comes to achieving the best possible project result, we spare no effort. We organize projects comprehensively. We create project status reports, work with digital documentation, and design highly specific work plans. Contact persons and project teams are set up across departments, and updating services can be implemented in the project.

That's project assembly with WASSERMANN.

We've already got some things ready for installation.

No example projects have yet been published. Please contact us directly for more information.