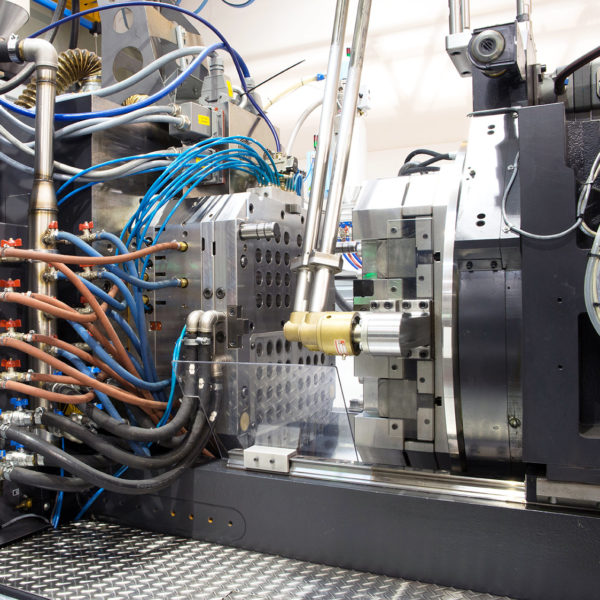

Machine construction

State-of-the-art manufacturing

of function-critical parts and ready-to-install modules

Your versatile supplier: our state-of-the-art metalworking means you can keep your promises of quality to your customers

Your customers are assured of the highest quality with machines that work reliably, with no breakdowns, around the clock when you need them. In our machine building, series parts such as milled parts and turned parts are an essential part of this assurance. Get the best components with contract manufacturing from the best suppliers.

High-quality production in a modern, automated machine facility

WASSERMANN is one of the few metal processing companies that are ideally positioned with regard to breadth of offerings and infrastructure. We manufacture milled parts and turned parts for series production, including precision parts with special requirements.

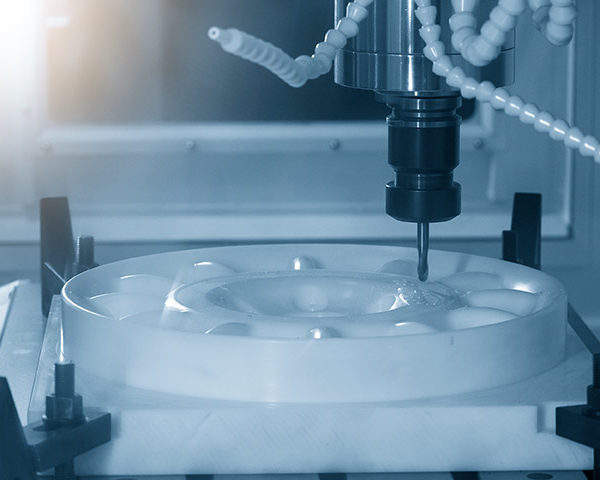

Our machine equipment includes modern production machines for CNC machining, allowing us to offer all the important metalworking methods. Our manufacturing is highly automated. That means we can provide series production quickly and cost-effectively. When needed, we can expand our automation – here as well, our expertise is outstanding.

Your advantages

Keep your market advantage with us- We know how to manufacture – thanks to extensive experience with an extremely wide range of geometries, materials, and processes.

- We invest continuously – State-of-the-art manufacturing is our claim: we are an established partner of major OEMs, and for this reason we generally have the most up-to-date production technology for CNC machining.

- We brainstorm along with you – give you our own suggestions for your project, because we always give our all.

- We get an early start – we go over solution options already during the development of components and assemblies

Overview of our services

for series production in machine building

Precision in series – We manufacture equipment for these industries

Reliable and precise components and assemblies

Our know-how

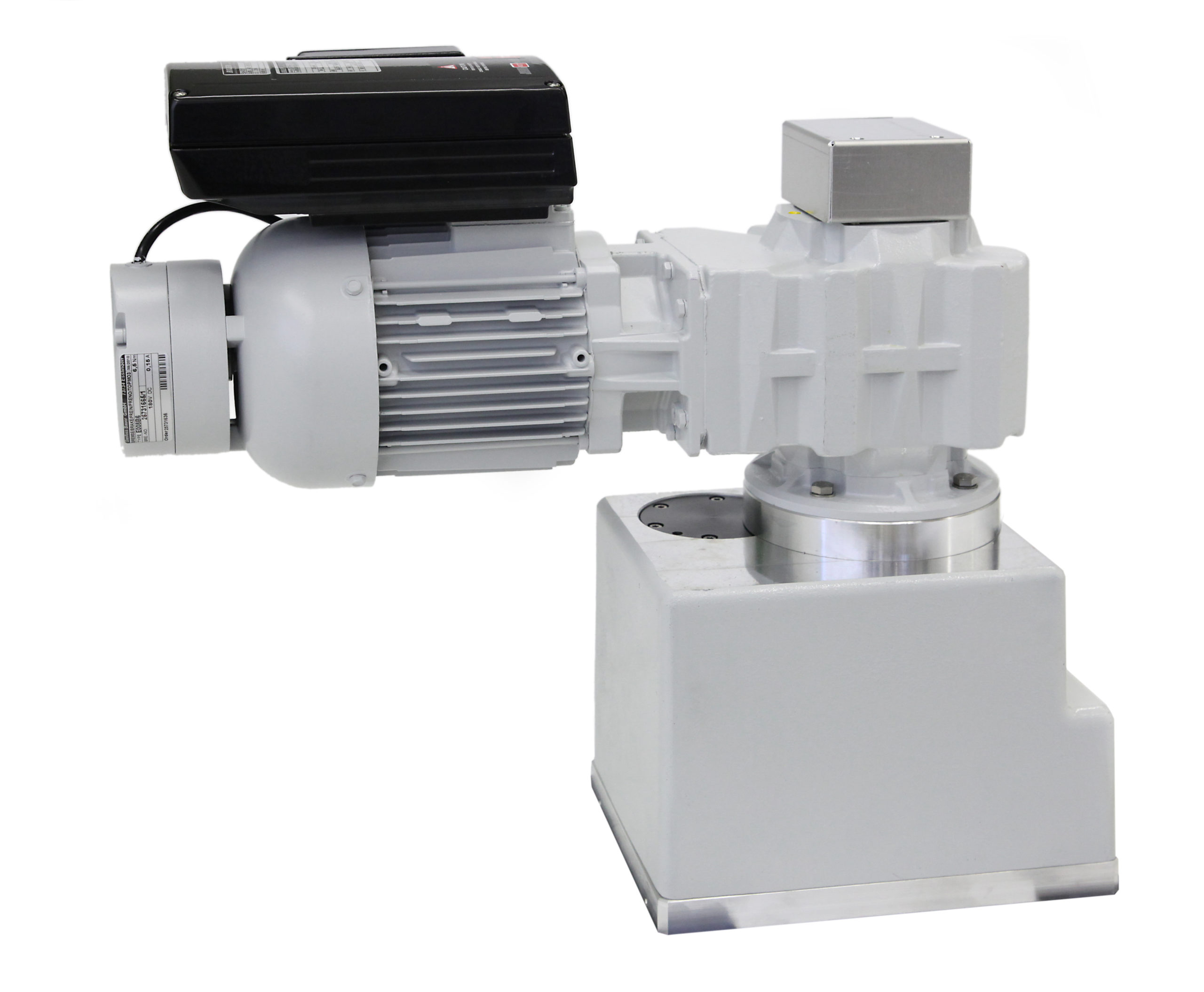

for your productsWhen parts and components are process-critical, they are what determine the long-term performance of a machine or plant. That means that process-critical parts are essential to success.A great deal of expertise goes into these components. For this know-how to be put to effective use, process-critical parts must be manufactured with the greatest care and precision. Anything less would be unserious.As your contract manufacturer, this care and precision is our promise to you. Our experience in design, machining, component assembly and quality assurance has already won over many customers,whose machines and systems are used in demanding industries such as aerospace, automotive manufacturing. and medical technology.

With these production technologies, we put metal into its best shape.

There are so many things that make us heroes in machine construction –

simplify your supplier management now!

WASSERMANN is the right machining company for you if you have high standards when it comes to function, reliability and quality assurance. We are the perfect fit if you need standard components and special parts manufactured in series, but you aren’t looking for small series production.We offer flexible solutions that will significantly simplify your supplier management. Our range of products, services, and potential series parts for machine construction is enormous.

Quality control at its best

Let your supplier take care of quality control, so you don’t have to spend time inspecting incoming goods. With our modern measuring and test equipment, we create lasting quality and document all results. We’re happy to have our quality assurance independently tested by audit.

Function-critical parts and ready-to-install modules

In WASSERMANN, you have a partner who manufactures function-critical parts and ready-to-install modules of outstanding quality – even for large quantities and recurring components.You’ll be able to assure your customers of a reliably high standard of quality as you move into the future. After all, promises kept are the best foundation for long-term customer relationships built on trust.

Nimble change: Our production: immediate adaptability as needed

Our production is highly automated. Nevertheless, we have designed our infrastructure to be so flexible that we can immediately switch to revision mode if you need variants, a design has been modified, or fluctuations need to be handled.No matter what change of course might present itself, we’ll find the way.