Tool changers –

Fast, durable, and prepared for any installation space

We didn't invent it. But we did make it what it is

When designing and manufacturing our changers, we make sure that they require as little maintenance as possible. That's why we mainly use cam controls and manufacture every changer ourselves with high standards of quality and precision.

Thanks to our patented automatic locking system, we can achieve maximum acceleration and thus bridge the distance between the magazine and spindle more quickly.

We have gained a lot of experience in the meantime. We make over 700 tool changers every year.

More than 700 tool changers per year

Your benefits

More dynamics for your tools

- Short change times – from 0.5 seconds per change

- High repeat accuracy – a prerequisite for consistently high production quality

- Robust – built for millions of change cycles

- Solid grip – patented positive locking system

- High availability – minimal maintenance

Gripper types

for reliable workflows

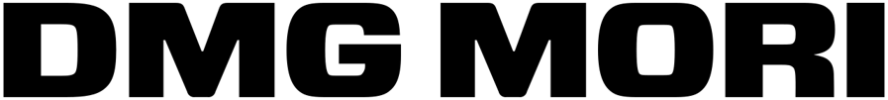

Hook gripper

- Radial insertion onto the tool means that no free movement of the spindle is necessary

- Mostly used for direct change between magazine and spindle without linear axes or additional handling

- Separate opening of the grippers enables safe tool handling even after the actual change process.

- During and after the actual changing process, the tools are held in the grippers by the patented mechanical automatic locking mechanism, which makes it impossible for the tools to tilt or twist.

Basic changers from WASSERMANN TECHNOLOGIE are tried and tested automation solutions. They offer the advantage that they can be delivered within a very short time and can be used immediately without any adjustments. All basic changers are cam-controlled and therefore offer precise and low-maintenance use in your machine tool.

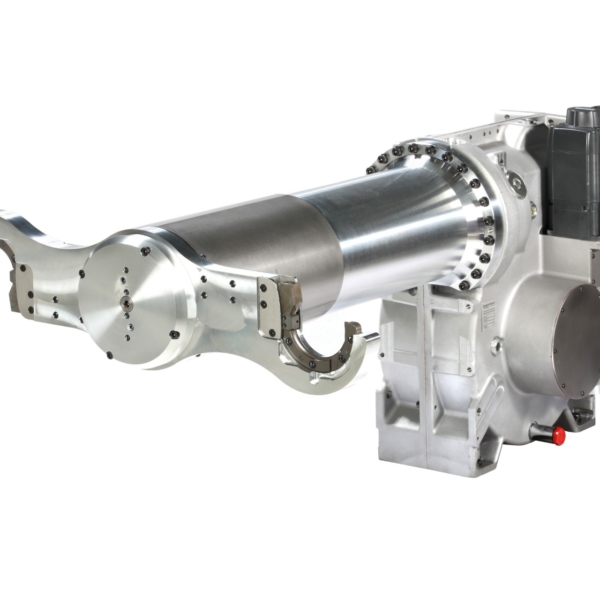

Fork gripper

- Direct exchange of tools between spindle and magazine is possible (without handling between the tool changer and tool magazine)

- The tool changers are usually used in combination with a linear axis to enable tangential insertion and to bridge the distance between the magazine and spindle

- Separate opening of the spindle-side gripper is possible while the magazine-side gripper is closed.

- During and after the actual changing process, the tools are held in the grippers by the patented mechanical automatic locking mechanism, which makes it impossible for the tools to tilt or twist.

- Cam-controlled or servomotor-controlled

Basic changers from WASSERMANN TECHNOLOGIE are tried and tested automation solutions. They offer the advantage that they can be delivered within a very short time and can be used immediately without any adjustments. All basic changers are cam-controlled and therefore offer precise and low-maintenance use in your machine tool.

Each one an example of the perfect handover

No example projects have yet been published. Please contact us directly for more information.

Don't see the right tool changing system? Looking for a special solution?

Changer for HSK-25, HSK-40 or Capto C4, for example

The selection of tool changers that we present here is perfectly suited for the HSK-25 to HSK-40 size range, which of course also applies to all other commonly used holders.

If you don't see what you're looking for here, just contact WASSERMANN. We'll work with you to develop your customized solution.

Medium-sized tools

Changer for SK-40, BT-40 or HSK-63, for example

These tool changers are the right choice for sizes HSK-50 to HSK-63 and the corresponding sizes of the other holders.

If the specification you require is not included, please contact WASSERMANN directly. We find your solution!

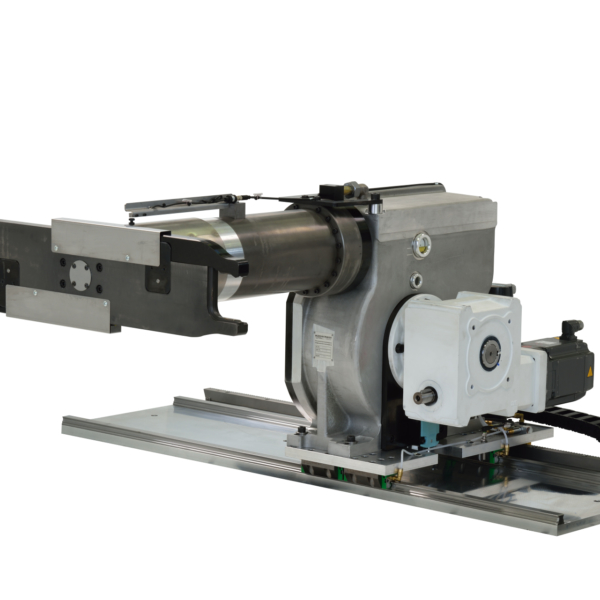

Large tools

Changer for HSK-80, Capto C10 or BT-50, for example

Heavy changer for large and heavy tools: The tool changers on this page are optimized for tools with HSK-80 to HSK-125 holders, as well as the analogous sizes for Capto, BT, SK and KM holders.

Don't see the changer you're looking for? Send us your detailed inquiry. We'll find the perfect solution for you.