Tool changing systems

Precisely coordinated magazine and changer systems

Efficiency starts with the right decision.

At first glance, a complex assembly of a tool magazine and tool changer might appear to be an unnecessary detour. But the fact is: A ready-to-install system is easier to integrate. And you solve two handling tasks at the same time on the tool side. So a tool changing system isn't really a detour, but the more efficient solution.

Tool changing systems from WASSERMANN combine tool changer and tool storage in one system. The result: Highly productive, ready-to-install solutions consisting of grippers and magazines you can use to fully automate your machines for subtractive manufacturing. We offer four systems as prepared, customizable products. In addition, we can develop the optimum system for you individually based on our modular system and manufacture it in series.

Getting the job done from start to finish

Your benefits

Achieve the maximum in tool handling

- Customized – systems made exactly to your specifications

- Simple – ready to install and connect

- Fast – individual solutions realized quickly

- Proven – in use for more than 20 years by international manufacturers

Make the most of the potential efficiency in tool handling with change systems from WASSERMANN

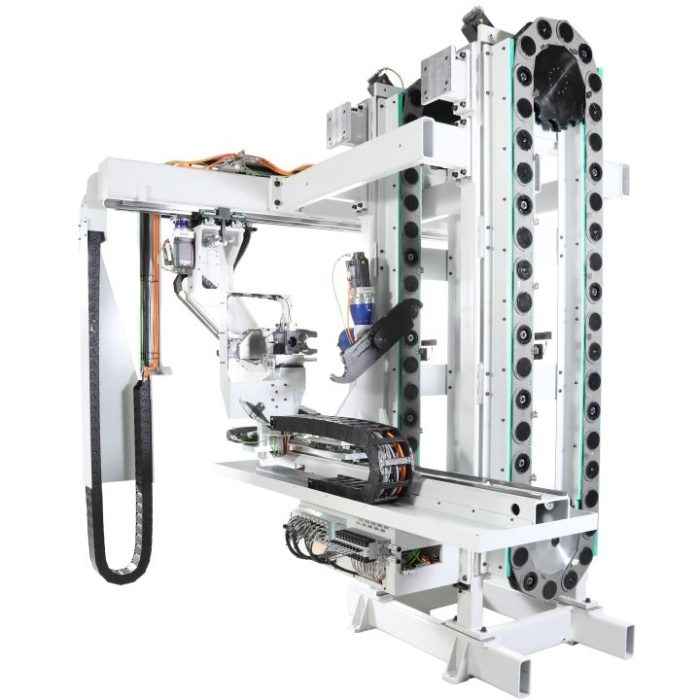

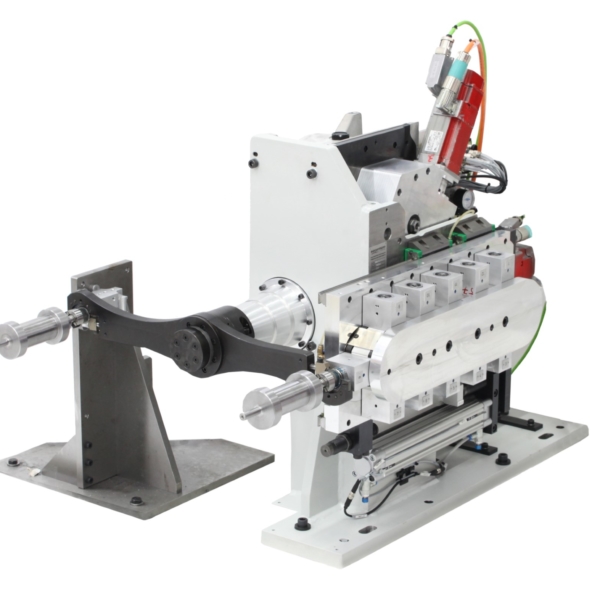

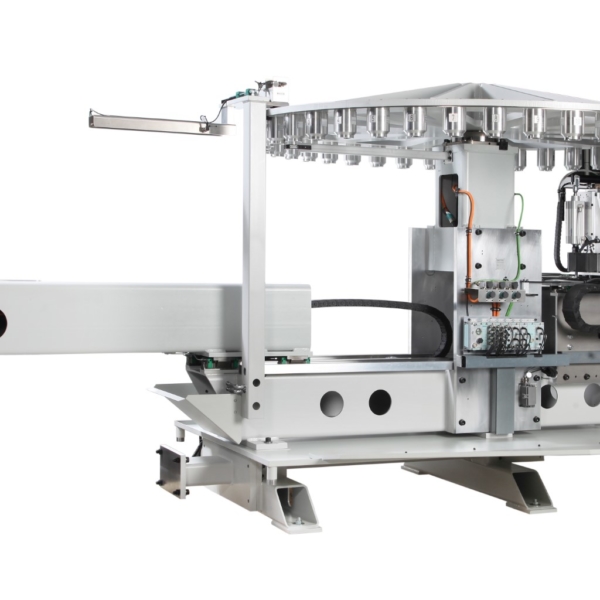

Changing systems for machining centers

Fast tool change times and simultaneous supplying of two spindles

Welcome to the extreme. Our changing systems for machining centers are designed for top performance. Benefit from high packing densities in small spaces, reduce unproductive time windows with super-fast tool changes, and have two spindles loaded with tools at the same time. Store up to 180 tools in the machine so that even complex and long production runs can be completed smoothly, with any standard tool holder. Take the productivity of your machines all the way to the top.

The best possible changing system can be realized if we work with you as an OEM from the very beginning. That way even highly complex systems can be integrated into your machine. For example, we've outfitted an Index R300 with two magazines, two changing systems for eleven axes. Tested, pre-assembled, ready to go. The tool changing system achieves a chip-to-chip time of just six seconds for both spindles and supplies seven positions with loading parallel to production. Come with us into the extreme.

These tool changing systems are designed for machining centers. They ensure fast changeover times and thus low idle times.

The systems are fully integrated into the machine and, due to the modular design, make it possible to realize different numbers of tools in one standard set-up. A loading bar is optionally available for loading parallel to production time.

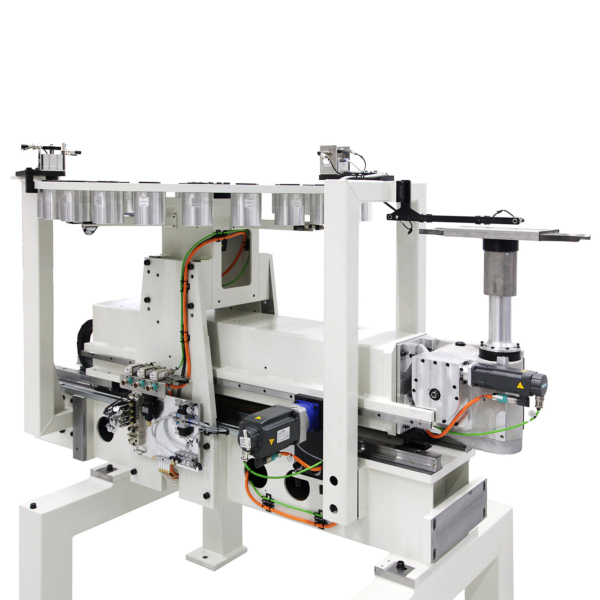

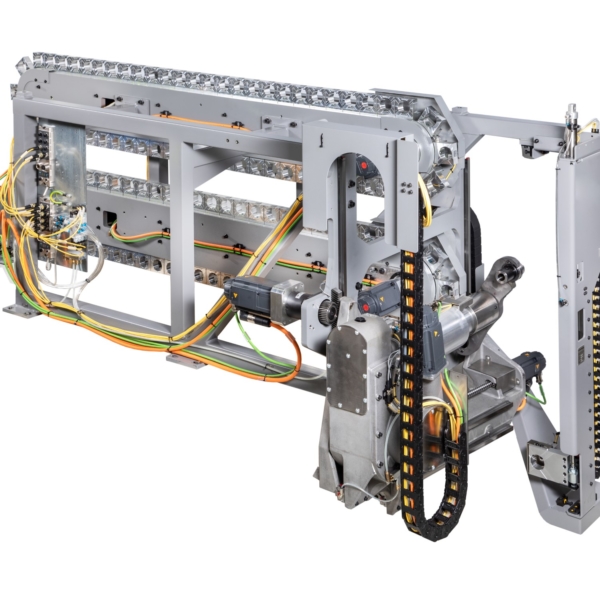

Changing systems – for large horizontal and vertical lathes.

Ideal for carousel lathes and large tools

Large machines work with large and heavy tools. We have the right changing systems to safely and precisely move and position tools up to 50 kg in weight and 1200 mm in length. Keep up to 180 tools ready for use in your machines, with standard tool holders and special holders.

With these solutions you can, for example, equip carousel lathes with two tool changing systems for two spindles. They can withstand high mechanical loads and are also suitable for large tools up to 50 kg in weight and 1200 mm in length.

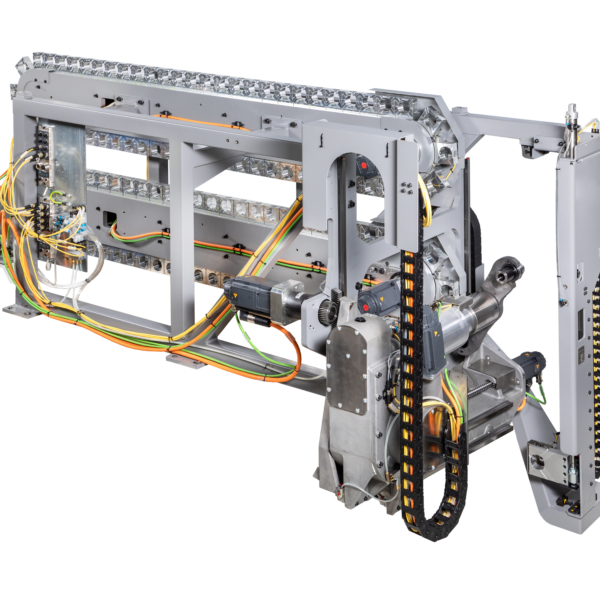

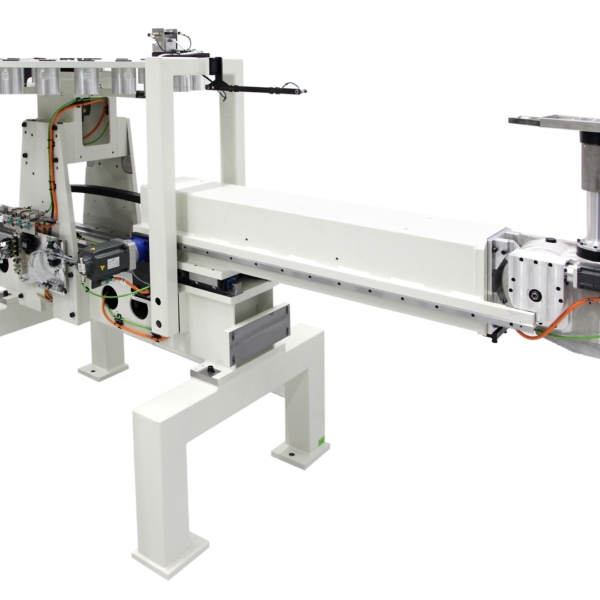

Changing systems for milling machines

These changing systems not only reliably bridge long travel distances between the magazine and spindle.

The tool changing systems for milling machines can meet many special requirements as well. These include additional nests for changing the milling head, changing between horizontal and vertical spindles or two different tool holders. The systems are stationary or can move with the gantry.

If required, they can also handle functions such as changing milling heads or changing to vertical and horizontal spindles, and can work with two different tool holders. The magazines of these changing systems offer space for up to 180 tools.

All standard tool holders can be used, as can special holders.

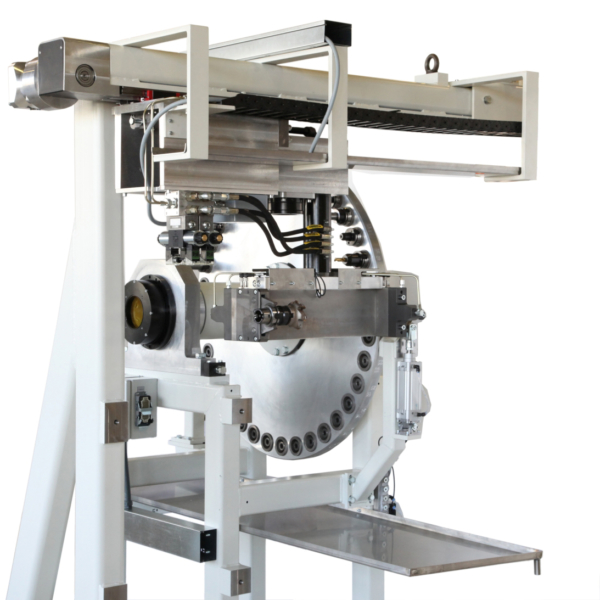

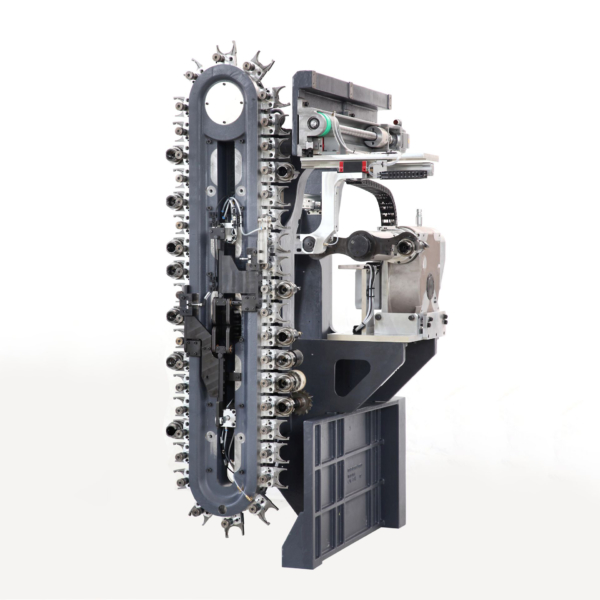

Changing systems for other production technologies

Developed and built for your machine – automation for special applications

Benefit from tried-and-tested technologies that go beyond typical manufacturing technologies such as turning or milling. The possible applications of WASSERMANN tool changing systems go far beyond these areas. If you want to automate tools for grinding, eroding, drilling, deep-hole drilling, finishing or other applications, you'll find the solution at WASSERMANN. You can store up to 180 tools with any holder in the magazines and keep them ready for the WASSERMANN fast tool changers.

If the requirements for your ready-to-install automation are a long way from the ordinary, we can do almost anything with our custom solutions.

We've developed solutions for machines in which the tools extend from the magazine in a hedgehog-like configuration. We've built systems that are extremely small and light. We've done a lot for the first time, and only a few twice. Here are a few examples:

- Grinding machine: 20 x HSK-100 holder, 50 kg grinding disk with a diameter of up to 400 mm

- Machine for end face machining of shafts: 12 x HSK-25 holder for tools with a weight of 3 kg and a diameter of 65 mm

- Grinding machines: 5-fold magazine with tool changer for machine loading and simultaneous control of the loading doors

No example projects have yet been published. Please contact us directly for more information.

Don't have the right tool changing system? Looking for a special solution?

Proven many times over, painstakingly inspected, tested in simulations close to real-world conditions

Support the process reliability and availability of your machines.

When you work with WASSERMANN, you get a robust and durable tool changing system. More than 1000 of our tool changing systems are in use worldwide, proving their worth every day.

After delivery, you can start using your tool changing system immediately.

All systems are fully adjusted, inspected, and extensively tested on our test benches for simulated practical use.

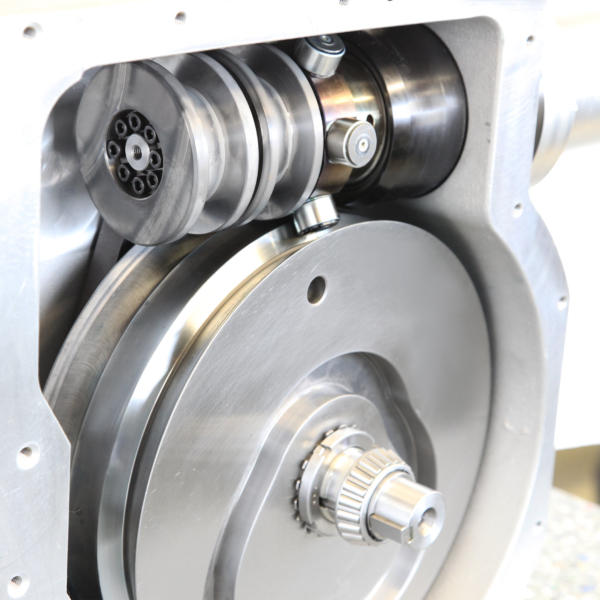

Always the right design: cam-controlled, servomotor-driven, or pneumatic

If you're looking for a technical solution that combines high changing speed, outstanding repeat accuracy, long service life and low maintenance, you should choose a changing system with a cam-controlled tool changer.

The design effort is greater than for a servomotor or pneumatic solution. But only cam controlling offers this specific combination of quality features.

Depending on the performance profile and application of a machine, tool changers with servomotors or pneumatics may be the more economical option. We've also developed many tailor-made solutions with these drive designs.

Take advantage of WASSERMANN's technological diversity to optimally prepare your machine.

Tool magazines for every installation space

In addition to tool handling, WASSERMANN also offers a wide range of options for storing tools:

- Plate link chain magazines,

- meander magazines,

- flat plate magazines,

- and standing disk magazines.

Each of these magazine designs has its strengths for optimally utilizing the installation space of a machine.

We equip each magazine individually, depending on the movement profile and speed. Thanks to tool holders with quiver or gripper designs, and options such as locking, we can cover every set of requirements.