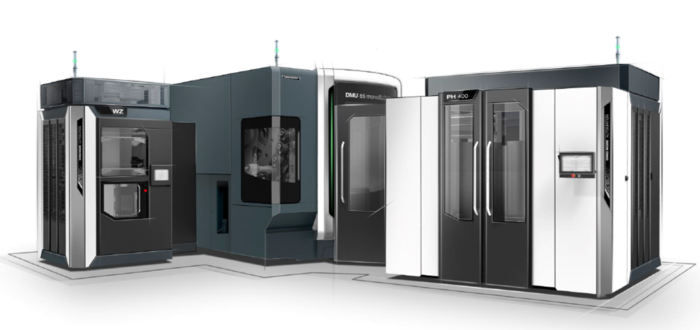

Tool storage and loading systems

for your machine series

Efficient tool management for modern production machines:

Modern production machines offer a wide range of options, but integrated solutions can no longer keep up with the increasing number of tools required. A future-proof option is therefore a tool storage system with sufficient reserves, particularly important for flexibility in automated, unmanned shifts.

Pallet automation often opens up completely new production concepts, but also requires extended tooling. Our WT terminals have proven themselves not only in retrofitting but also in standard use. Rely on our solutions to always have the tools you need directly at your machine.

Always the required tools at the machine

Get your machine up to speed

The advantages of TOOL terminals

- Space-saving and efficient – High tool density with up to 552 tools on just 3.5 m² – saves valuable space in production.

- Versatile and customizable – Universally usable with all standard tool holders, with three basic architectures for flexible configurations.

- Open and economical – Open storage with interfaces to tool management, tool presetting and production, ensures a short payoff time.

- Increases productivity – Reduces downtimes due to twinned tools and increases machine productivity.

- Customized and user-friendly – A modular design allows almost unlimited variants, and simplifies the implementation of special requests without a large outlay.

- Powerful and integration-friendly – Series-optimized design and modular structure for simple service and support; enables easy integration into OEM machines across variants and series.

Individual branding

Customized terminals according to OEM specifications

Our terminals are designed exactly according to the customer's specifications so that they fit seamlessly into the design of the OEM machine. The technical features are based on proven automation solutions for machining companies and ensure a sophisticated system with high performance that can be easily integrated into the OEM machine.

Our automation solution not only applies across variants and series, but also makes it easy to integrate the terminals into the design of the machine housing. Thanks to their modular design, our terminals offer almost unlimited variants that make it possible to realize individual requirements and special requests from customers without a large effort.

The terminals are easy to integrate into different automation environments, be it tool ID systems, control systems or various PLC interfaces and generations. The series-optimized design and modular structure not only facilitate service and support, but also make it easier to stock replacement parts for frictionless integration and maintenance.

As an additional magazine on the machine, the terminal exchanges tools with the internal magazine of the machine. There are three options for controlling the terminal.

- Without a dedicated control system:

The machine controller controls the terminal.

- With sequence controller and IO link interface:

The machine controller manages the tools.

The terminal sequence controller coordinates the handling in the terminal and the transfer of tools to the machine magazine.

- With sequence controller, own management, and IO interface:

The terminal controller controls the sequence and manages the tools in the terminal.

In addition, the terminal controller uses an interface to transfer control signals and tool data to the machine controller.

Integration of data from the tool setup is also possible.

As a direct magazine for machines without tool magazine

The terminal can be used as a direct magazine for machine tools without a magazine.

This allows you to expand your production options by creating external storage slots with the terminal and automating the tool transfer. The tools are moved to the spindle directly or through an intermediate handling unit.

The terminal is controlled by the machine in this case.

As a central magazine for several manufacturing systems

As a central magazine, an individual terminal supplies the magazines of several manufacturing systems with tools to expand the storage capacities of the machines.

The terminal is equipped with a sequence controller, tool management, and an interface to the respective machine controllers. This allows control signals and tool data to be exchanged quickly and without errors. RFID technology and a link to a tool setup unit are optionally also possible.

The tools are requested either by the main computer or by the machine controller. A handling system carries out the reliable tool exchange between the terminal and the tool magazine of the connected machines.

As a stand-alone storage unit for prepared tools

As a stand-alone storage unit, a terminal is a tool storage system with a large capacity and a small footprint.

Tool data can optionally be read in via RFID without errors and the terminal uses the data to find the optimum storage slot for the tool. A tool management system can be connected at any time and data exchange with a tool setup unit is also possible. In addition to all this, the terminal can directly transfer tool data to the CNC machine digitally.

This eliminates manual input – a key cause for scrap or even crashes.

No example projects have yet been published. Please contact us directly for more information.

Three architectures

for your machine series

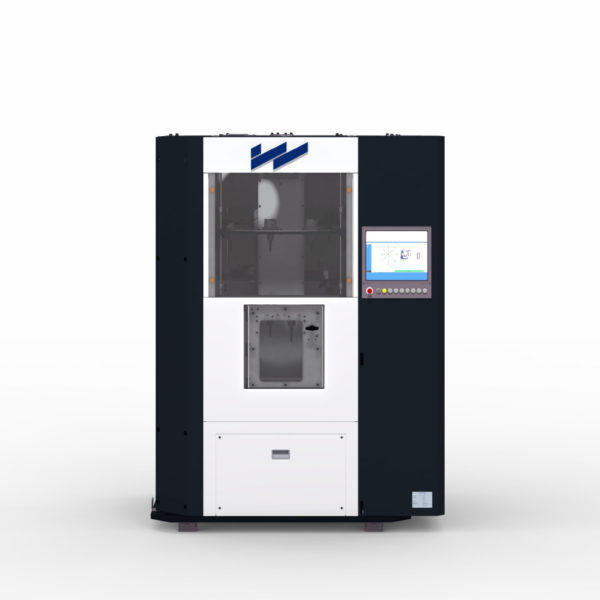

TOOL-S: the economical entry-level

The round shelves with the smallest footprint and 3 to 7 levels

Your tools in the round. The TOOL-S is a round shelf storage system with 3 to 7 shelf levels. Pack up to 350 tools together on a small footprint. This gives you many times the capacity of conventional machine-adjacent magazines. TOOL-S can be run on almost any machine, allowing any production facility to implement automated tool handling or expand the machine-adjacent magazines.

You can use the modular system of TOOL-S to achieve the exact configuration for your automated tool storage system. Please contact us for an in-person consultation.

TOOL-S

- S for shelf: The compact shelf system for up to 350 tools can be combined with almost any machine.

TOOL-D: the space saver

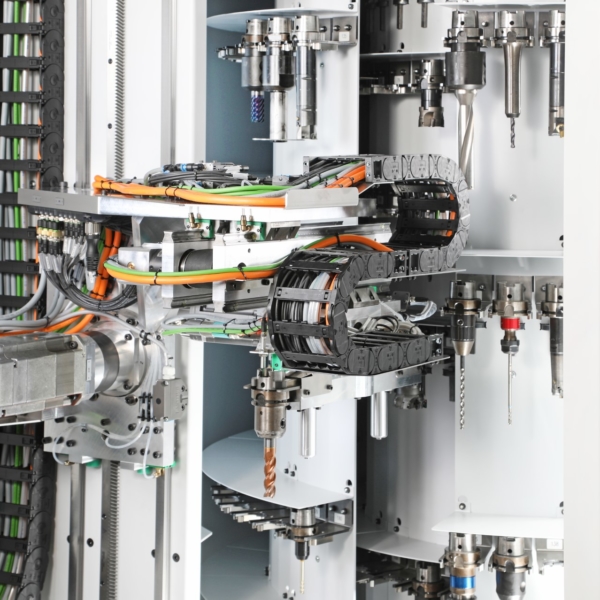

The patented drum magazine with the highest packing density

We believe that tool availability on a machine should no longer slow down production. So we kept working on the problem of packing density until we found a new storage concept: TOOL-D, with D for drum: It works with up to three drums that rotate inside one another, each with up to 6 levels. This creates space for up to 1000 tools on a very small footprint.

The standard version can already hold up to 570 tools, and with the options of the modular TOOL terminal system, you can easily adapt the capacity to your requirements.

Ask us about it. So the number of storage slots on your machine tool no longer sets the limits.

TOOL-D

- D for drum: The standard version of the space saver with patented multi-drum can hold up to 552 tools – and more on request.

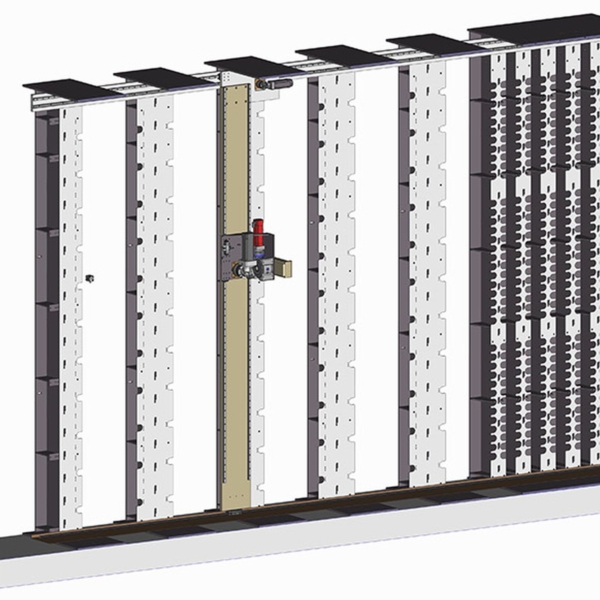

TOOL-L: the linear storage system with unlimited expansions

Simply let your storage capacities grow gradually.

Your production should have room to grow in the years to come, for example with additional machine tools, and these should ideally be able to work with more tools than specified by the manufacturer. TOOL-L gives you a solution that can grow, integrating additional machines in a linear pattern as and when required.

TOOL-L is limited only by the available space in the workshop. You can start with a capacity of 500 tools and use the modular system to expand it as required, almost without limits. The more space you have available next to your machine, the better – because this automatically increases the feasible storage capacity.

If you want maximum capacity and plenty of expansion options, please contact us about your individual TOOL-L.

TOOL-L

- L for linear: storage space for far more than 500 tools. The maximum capacity depends primarily on the available floor space.