Storage and loading systems with clamping pallets

for your machine series

Maximum productivity for your machine tool through automated pallet handling

Automated handling of workpieces on clamping pallets not only provides a significant productivity boost for your machine tool, but also quickly pays for itself for your customers. Our WORK terminal series from WASSERMANN offers the ideal solution for powerful and flexible automation of your machine tools.

Why buy automation?

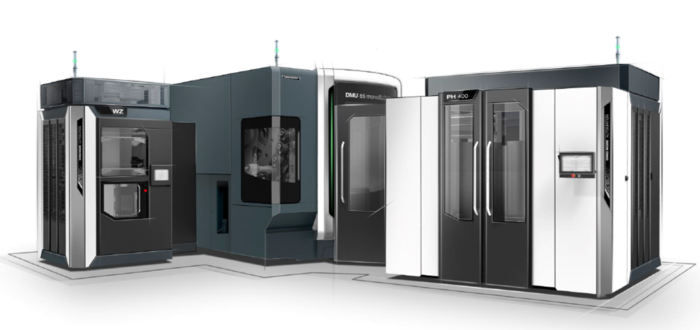

The market is increasingly demanding complete solutions that combine machine tools with pallet automation. OEMs need reliable, flexible solutions that are easy to connect. Our terminals let you get more out of your machines. So they can respond quickly to the increasing demand for standard complete systems. The automation of machine tools is highly individual, and requires a reliable platform and a modular system that can be easily connected to different machines. The WORK terminals offer a solution that can be used across all variants and can be adapted to customer-specific requirements.

Easy integration into different environments

The WORK terminals can be easily integrated into different automation environments, from pallet ID systems to control systems to different PLC interfaces and generations. The series-optimized design and modular structure facilitate service and support as well as spare parts inventory.

For manufacturers of machine tools – WORK terminals from WASSERMANN. Your solution for maximum production performance.

Maximum efficiency through

storage and loading systems for clamping pallets- Productivity optimization – more spindle hours on your machine tool through unmanned shifts.

- Space-saving solution – high pallet density on a small footprint saves space.

- Economical investment –pays for itself quickly, and that means faster profit.

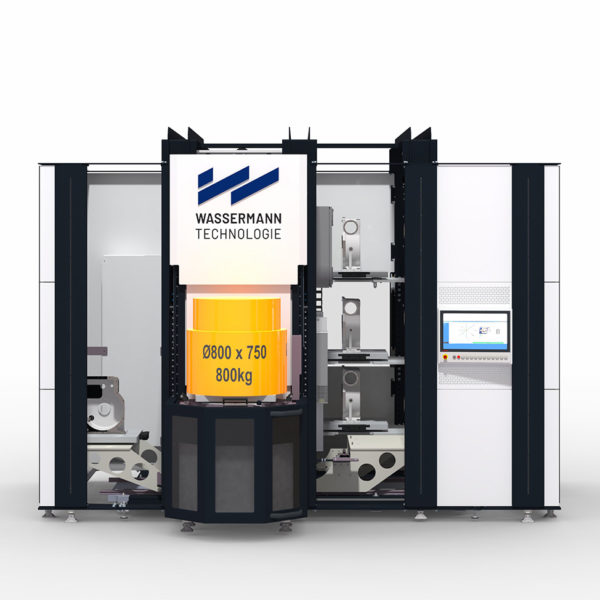

- Versatile in use –load capacity handles high transfer weights; can be used with different machines and centers.

- Durable and robust – high transfer weights of up to 800 kg for demanding manufacturing jobs.

Individual branding Customized terminals according to OEM specifications

Our terminals are designed exactly according to the customer's specifications so that they fit seamlessly into the design of the OEM machine. The technical features are based on proven automation solutions for machining companies and ensure a sophisticated system with high performance that can be easily integrated into the OEM machine.

Our automation solution not only applies across variants and series, but also makes it easy to integrate the terminals into the design of the machine housing. Thanks to their modular design, our terminals offer almost unlimited variants that make it possible to realize individual requirements and special requests from customers without a large effort.

The terminals are easy to integrate into different automation environments, be it tool ID systems, control systems or various PLC interfaces and generations. The series-optimized design and modular structure not only facilitate service and support, but also make it easier to stock replacement parts for frictionless integration and maintenance.

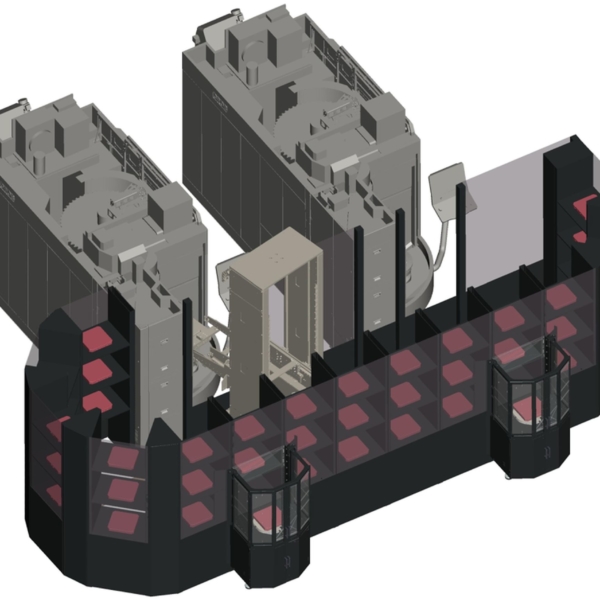

Three application scenarios of finished automation solutions on your machine tool

Find your finished workpiece automation

Three architectures for your workpiece storage system

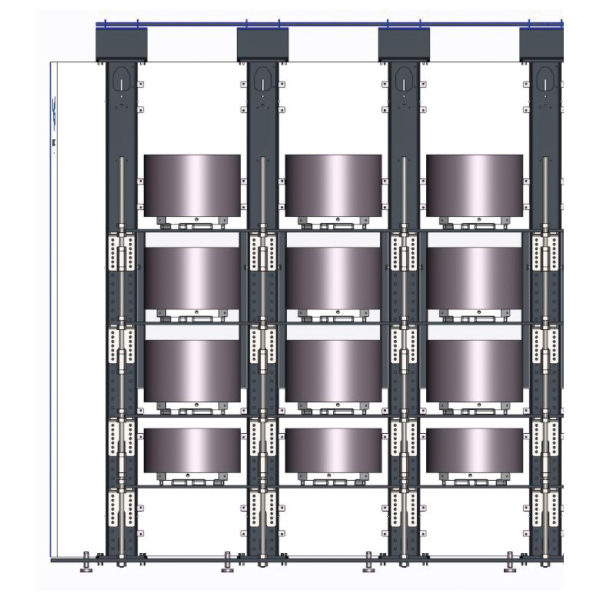

WORK-S: the standardized round shelf with plenty of space for adjustments

If you want to automate pallet feeding for one to two machine tools, WORK-S will meet your requirements. The S stands for shelf – the design as a shelf magazine. With up to 6 levels, the compact, cost-effective storage system offers space for up to 44/81 pallets of size d148 with dimensions up to 630 x 630 mm. Transfer weights up to 800 kg are possible.

WORK-S can be combined with almost any machine and impresses with a small footprint.

Our Terminal team can adapt WORK-S to your requirements. You're already using a high packing density in the basic configuration as a round shelf storage system. But there's always more. We can significantly increase the packing density by equipping your WORK-S with the patented WASSERMANN multi-drum.

WORK-S series

- S for shelf – the compact, cost-effective shelf storage system for up to 44 pallets

- Transfer weights up to 800 kg

- Round shelves with up to 6 levels