Tool storage systems and loading systems –

the TOOL terminals

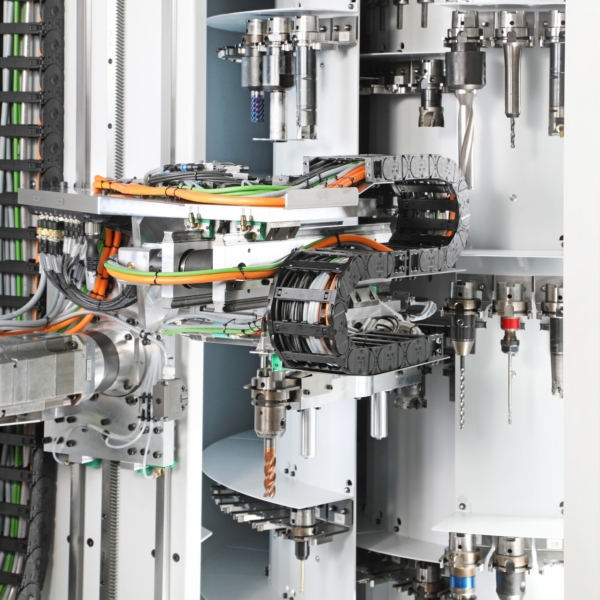

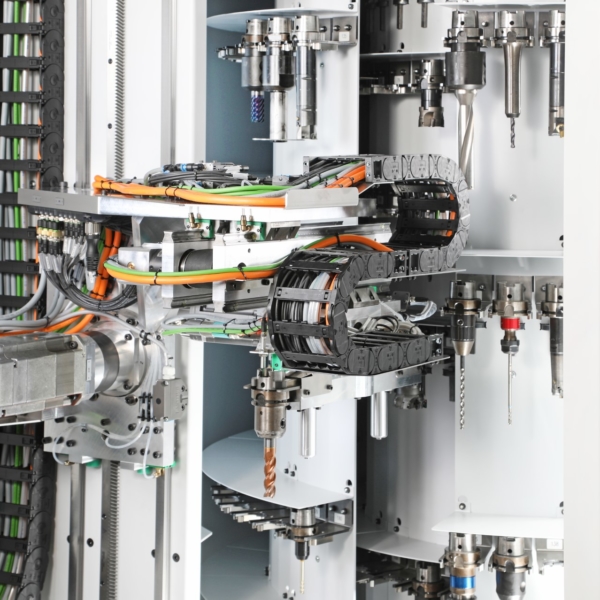

Intelligent tool handling directly on the machine

With the TOOL terminals from WASSERMANN, you switch your tools to automatic mode. You benefit from a well thought-out configuration, powerful software, and a fast, robust mechanical system. Automation and set-up during production time enable you to reduce set-up times, while the intelligent tool allocation in our software accelerates the tool changing processes.

Your advantages: more spindle hours, higher throughput, more turnover potential

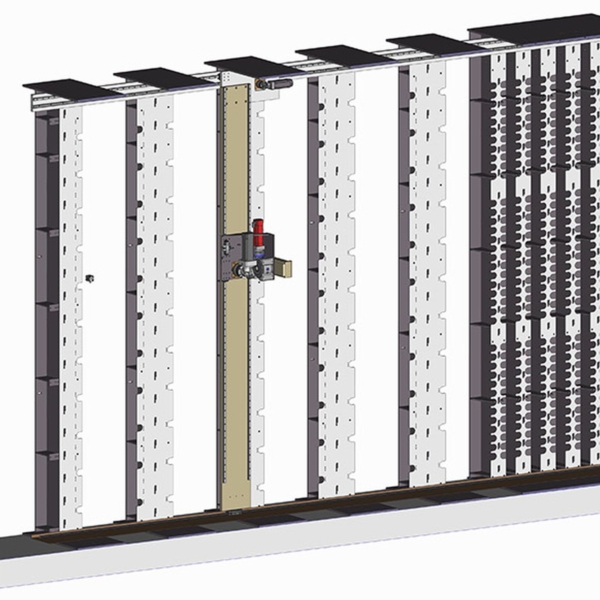

Use the modular principle for configuration. Select the design of your tool storage system based on the desired capacity range. Then decide on details such as the exact capacity, mounts, tool length, and other features.

Your advantages

Develop productivity from order- Space-saving – high tool density, e.g. 552 tools on only 3.5 m²!

- All-rounder – for all common tool mounts

- Open – storage system with interfaces to tool management, tool setup, and production

- Economical – short amortization period

- Market-oriented – complex jobs with existing machines

- Productive – reducing downtime with sister tools

- Attractive – a modern production environment for your team

- Demand-based – three basic architectures for flexible configurations

CNC automation from WASSERMANN TECHNOLOGIE GmbH Customized solutions for your production

The TOOL terminals: configure your success factor

Three architectures for your tool storage system

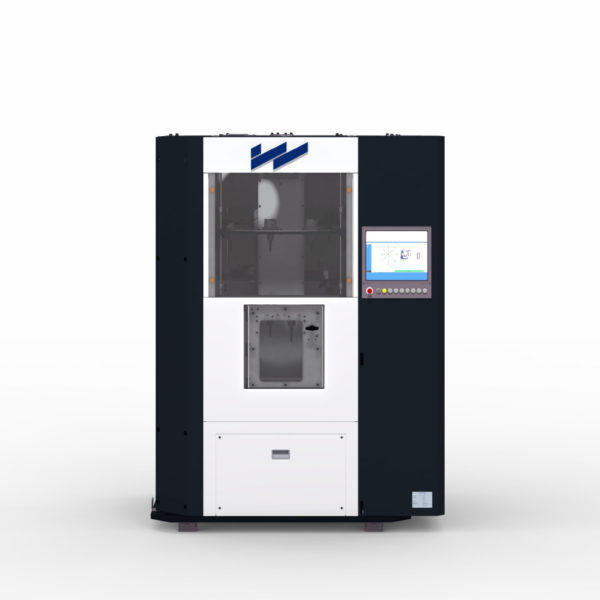

TOOL-S: the economical entry-level

The round shelves with the smallest footprint and 3 to 7 levels

Your tools in the round. The TOOL-S is a round shelf storage system with 3 to 7 shelf levels. Pack up to 350 tools together on a small footprint. This gives you many times the capacity of conventional machine-adjacent magazines. TOOL-S can be run on almost any machine, allowing any production facility to implement automated tool handling or expand the machine-adjacent magazines.

You can use the modular system of TOOL-S to achieve the exact configuration for your automated tool storage system. Please contact us for an in-person consultation.

TOOL-S

- S for shelf: The compact shelf system for up to 350 tools can be combined with almost any machine.

Application options for your TOOL terminal

As an additional magazine directly next to the machine tool

As an additional magazine on the machine, the terminal exchanges tools with the internal magazine of the machine. There are three options for controlling the terminal.

- Without a dedicated control system:

The machine controller controls the terminal. - With sequence controller and IO link interface:

The machine controller manages the tools.

The terminal sequence controller coordinates the handling in the terminal and the transfer of tools to the machine magazine. - With sequence controller, own management, and IO interface:

The terminal controller controls the sequence and manages the tools in the terminal.

In addition, the terminal controller uses an interface to transfer control signals and tool data to the machine controller.

Integration of data from the tool setup is also possible.