Tool magazines –

stored productivity for your machine

Developed, built and put into series production for you by true automation enthusiasts.

Since 2005, we've been developing, designing and manufacturing tool magazines whose design and capacity precisely meet the requirements of our OEM customers. With a tool magazine from WASSERMANN, the production areas of your CNC machines will be reliably and precisely supplied with tools for many years to come.

Millions of tools are already stored in WASSERMANN tool magazines. Every day. Around the world.

Our holder designs are just as flexible. We work with quivers, tongs, and can also reliably implement other options. You can combine any magazine with tool changers or use it as a pick-up magazine.

Thanks to our modular system for tool magazines, we are able to provide the tool magazines that will best support your machine concepts.

If you want to further improve the performance of machine tools, you'll find the best tool magazine at WASSERMANN.

What's on your wish list?

Your benefits

More dynamics for your tools

- High productivity – minimum access times

- Cam control – fast yet precise magazine movement

- More storage positions in the magazine – many production options for the machine

- Adaptable – flexible integration into every machine design

- Space-optimized implementation – optimal use of the machine footprint

- Heavy-duty mechanics – low maintenance

Magazine variants

In action every day

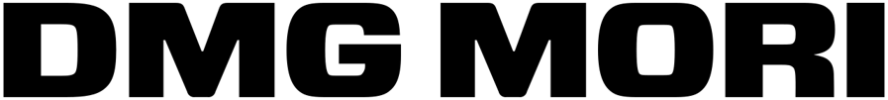

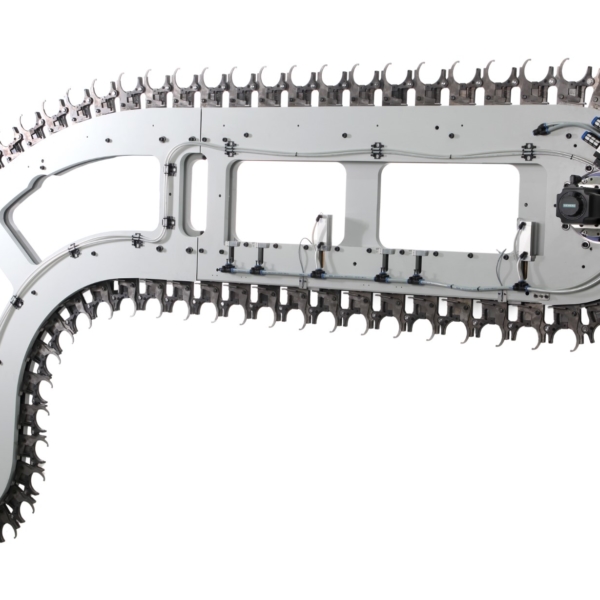

Chain and plate chain magazines – plenty of room in the smallest of spaces

If you're planning to equip your machines with a magazine that stores many tools, keeps changeover times short thanks to its low moving mass, and can be integrated into a small installation space:

Chain and plate chain magazines from WASSERMANN are your best option.

We offer these magazine types for all common tool holders and for special holders. Store up to 180 tools in your machines. Always ready for use, very close to the spindles.

Tell us about the perfect tool magazine for you.

The examples you see here are just a few of the options. We can adapt all important parameters, such as installation position, tool length, tool weight, capacity, change speed and many more, precisely to your requirements. Ask our experts We want to give your machine a precisely specified tool magazine.

So your customers will find the perfect conditions for perfect production.

Plate and disk magazines: the exquisite little ones, for up to 40 tools

With WASSERMANN plate and disk magazines, tool provision is guaranteed to run smoothly.

If the machine footprint isn't a main concern and a capacity of up to 40 tools is enough, we recommend plate and disk magazines. They can be configured for all standard tool holders and store tools with an individual weight of up to 50 kg.

Because we design and manufacture our own tools, we can adapt all features to your requirements on request. We find your solution!

No example projects have yet been published. Please contact us directly for more information.

Don't see the right tool magazine? Looking for a special solution?

Today, fractions of a second matter. With frequent tool changes, the maximum acceleration that a tool magazine can reach is a factor in success and cost-effectiveness. How securely a tool could be fixed in the magazine was for a long time a factor that limited the achievable acceleration.

To remove this speed limit, WASSERMANN has developed an active positive locking system. This holds even heavy tools reliably in place at high accelerations. With their high working speed, WASSERMANN tool magazines are leading the way to a new level of performance. Magazine with spring-loaded locking mechanisms are clearly at a disadvantage now, especially in meander magazines.

Now you too can shorten tool provision times in your machines.

Perfectly integrated magazines, with many options. So tools deliver top performance right from the start.

Keeping a tool stock close to the machine spindles increases the performance of a CNC machine. Since the 1980s, tool magazines have been the key component in realizing this increase in performance. Since then, user wish lists have gotten longer. Minimal access times, fast yet precise magazine movement, more storage space, all on an even smaller footprint and with the best possible integration in every machine design.

What's on your wish list? Thanks to our modular system for tool magazines, we are able to provide the tool magazines that will best support your machine concepts. If you want to further improve the performance of machine tools, you'll find the best tool magazine at WASSERMANN. Developed, built and put into series production for you by true automation enthusiasts.

Develop and produce with the tool magazine specialists

Your customers want to produce with high-end quality using your machines. To get this quality, it's crucial for the entire mechanical system of the machine to operate with the lowest possible tolerances over its entire useful life.

Tool handling inside the machine starts with the tool magazine. Compromising on the precision of the magazine increases the risk that the tolerances of the machine can't be permanently maintained. This gradually reduces the production quality.

Only if a tool magazine is optimized to position tools with high precision can the tool be picked up by the gripper and transferred to the spindle precisely. Even slight deviations in the positioning accuracy of the magazine increase wear on the gripper mechanism, and put additional strain on the spindle due to collisions.

You can prevent these reductions in quality with tool magazines from WASSERMANN. You guarantee your customers a long service life of the machine, avoid follow-up costs due to repairs, and ensure consistently high production precision in the high-end sector.