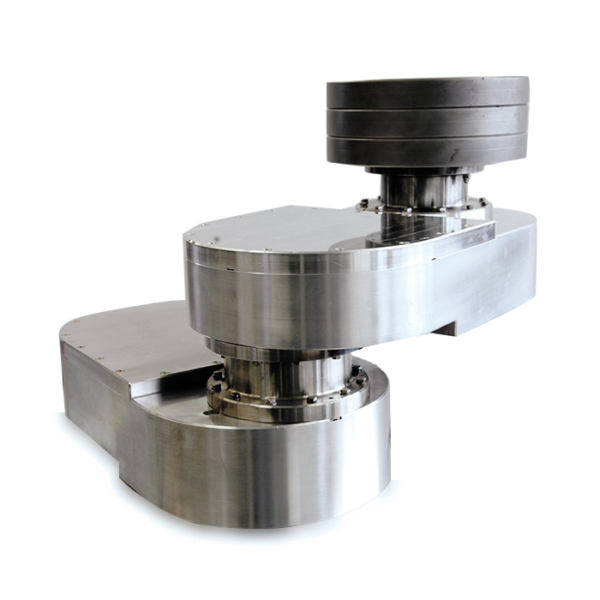

Rotary lift transfer devices

for complex motion profiles

Fail-safe operation at high cycle rates

Cam-controlled rotary lift transfer devices leave pneumatics and electric drives far behind when you need a fast, precise and reliable handling process in automation. This technology enables you to achieve consistently high cycle rates with several operations per second. You can be sure that the mechanics will run robustly and fail-safe, cycle after cycle for years. Collisions and accidents due to malfunctions in pneumatic or electronic components are a thing of the past.

Use the mechanical programming of sophisticated motion profiles

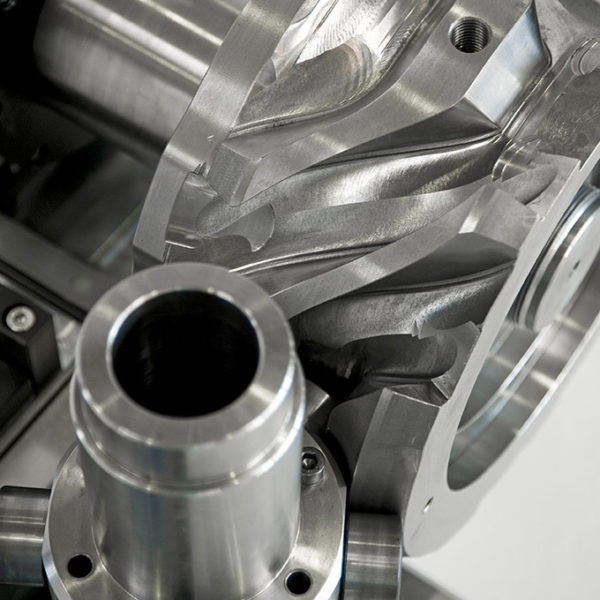

The technical basis is no secret: mechanical control cams and cam gears. But very few manufacturers have mastered both the complex calculations involved in design and the high precision required in production.

WASSERMANN has been designing and manufacturing mechanical automation solutions with control cams and cam gears for over 30 years. In other words: We know how to precisely superimpose rotational and translational movements. We can also mechanically program sophisticated motion profiles for handling in your machines and systems with an accuracy down to a few milliseconds.

Your benefits

with rotary lift transfer devices for handling tasks- Fast and precise – high speed, continuous availability 24/7, constant precision

- Robust and resilient – stable handling even at high temperatures, e.g. in hardening processes

- Reliable and easy to maintain – runs precisely over thousands of operating hours and provides easy access for servicing

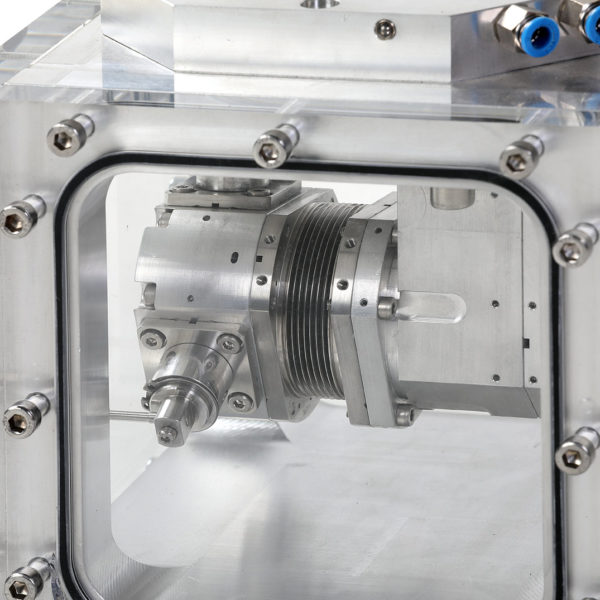

- For success in extreme conditions – designed for extreme environmental parameters in cleanrooms, including conditions with high exposure to dust, moisture, or high temperatures

These rotary lift transfer devices are already speeding up our customers' handling processes

Quality in automation and the story behind it

Quality under all conditions

The working environment can be uncomfortable when automating with rotary lift transfer devices from WASSERMANN. When high temperatures, high pressures, or heavy mechanical loads occur in a machine, our automation is prepared for them.

We design for challenging applications and manufacture for long service life. The quality of our components and systems is uncompromising, because it's not always easy to change or repair a part deep inside a textile machine or filling system.

Our cam-controlled tool changers and changing systems are just one example of how reliable WASSERMANN is. They complete millions of cycles and are in top working shape at every maintenance interval, even when transfer weights of 50 kg have to be moved on a daily basis.

At WASSERMANN, quality is more than just a promise. Quality is a verifiable service.