Automation success stories

Case study of a medium-sized company

Project successes

Significant increase in production output

More throughput with the same number of employees

Elimination of setup times through setup parallel to production time

Short payoff time leads quickly to profit

Excerpt

Over more than 50 years of company history, HILLMER Maschinenbau GmbH has made a name for itself as a supplier in a wide range of business fields. Their long-standing partners include customers from plant engineering and the automotive, mechanical engineering, printing and defense industries. Based on continuous market analysis, they have invested regularly in state-of-the-art machines and automation technology. Due to the shortage of skilled workers, the VHC 2 machining center of AXA was only able to carry out its work in manned shifts, especially for series production and various repeat parts. Thanks to pallet automation, HILLMER is now also able to run production completely unmanned, in night shifts and on weekends. Economic growth and greater efficiency, without any additional personnel costs.

Automation solutions

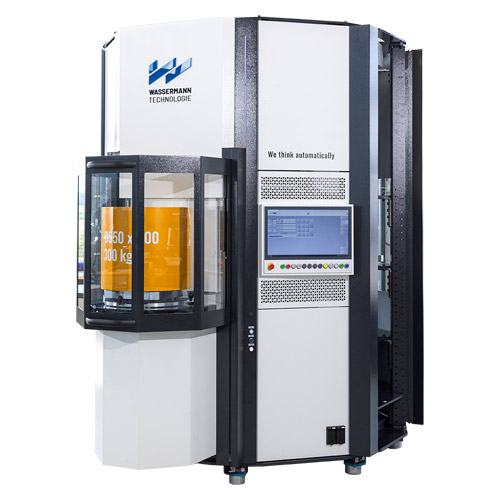

WORK-S Terminal

as storage and loading systems for clamping pallets