Mechanically programmed

for maximum repeat accuracy and speed

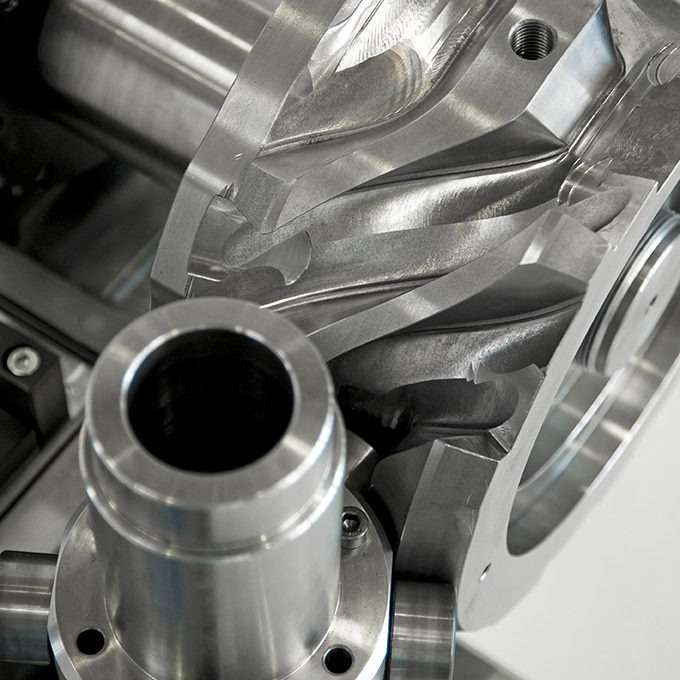

Control cams up to the top league: designed and manufactured by WASSERMANN

As experienced experts in industrial control cams and cam gears, produced in series, we have mastered the entire range of this technology right up to the high-end segment of high-performance cams. These are characterized by, among other things, ground surfaces, so the machine runs even more smoothly.

We can create all geometries relevant for modern mechanical control cams: globoidal cams, cone globoidal cams, cylinder cams, disk cams, double disk cams, complementary cams, and axial cams. With our expertise in geometries, we design exactly the cam that best meets your requirements.

We design, calculate and manufacture cams that ensure high productivity in filling systems, packaging machines, textile machines, printing machines and other applications.

Custom cam gears as special solutions

There are standard scenarios, and then there are special challenges. No matter what the situation, we find the solution. Let us clarify the specific load and movement profiles for your application in an initial consultation. We've already developed many cam gears that don't fit any standard pattern.

Precision guides for special applications

WASSERMANN is flexible. You decide the extent to which you want to involve us in your project. We can take on the entire package or only partial projects. If you don't need a complete cam drive, but only project-specific components or know-how, we're also happy to be part of your team as co-developers or production experts.

We offer you industrial process steps such as machining, heat treatment, grinding, straightening, or manual machining or setting of ready-to-install components or component groups.

Reproducible high quality in series

Individual parts and very small series are not our main focus. We focus instead on series starting from medium quantities upwards that have to have reproducible and precise production quality. This is where our strengths as experienced machinists come into play, as we meet your requirements consistently and reliably with every series run.

Your advantages

Precise, fast, durable: Ideal for pick-and-place and many other processes- Repeat accuracy – millimeter-precise control with every cycle

- Mechanically resilient – works reliably under high temperatures and pressures and in environments with dirt and dust

- Optimized – durable and service-friendly design

- Small tolerances – precisely manufactured, pinpoint movements

- Easy to install – simple integration into the machine

- Efficient procurement – calculation, design, and production from a single source

- Cost-effective operation – lower infrastructure costs and hardly any running compared to a pneumatics solution

Overview of our control cams and cam gears

components and assemblies

Reliable and precise Control cams and cam gears

Our know-how

for your products- as a build-to-print partner for production and assembly

- for optimizing existing solutions

- for further developing systems and their parts

Range of services for control cams and cam gears

The measure of all things in cam and gear design

Take advantage of all the benefits of modern and precisely calculated control cams and cam gears. We take all influencing parameters into account, from design to integration into your system. We manufacture the best solution for your requirements profile.

- Movement in all directions – stepping, pendulum, lifting and stroke movements.

- Coordinated pace – superimpose multiple movements

- Perfect calculation – exact calculation of movement sequences

- From initial idea to function – design of cam gears including load and strength analyses

- Computing power for your solution – calculation using the program Optimus Motus, as well as CAD and CAM programming

Calculation, design, and manufacturing from one source

Based on control cams and cam gears, we develop fast and precise mechanical automation solutions. Two things set us apart: WASSERMANN has all the expertise in-house that makes the difference for calculation, design, and production. And we have become so familiar with this technology that we can exploit its potential even under very strict conditions.

This special constellation is almost a unique feature. We can provide the right control cam or cam gear even when your machine process tolerances are tight and the cycle time needs to be high.

To summarize our experience in this area as a number: 250,000: that's how many cam controllers we have already manufactured – at least.

First class treatment for your application: High-performance cams, special solutions, special applications

What makes high-performance control cams particularly demanding

Cams can become process-critical if they run too loudly, show too much wear, or are not adequately secured against the lifting of guided elements such as chains.

We have detailed knowledge about how control cams work. That's why we are meticulous in the design and manufacture of cams and control gears. Paying close attention is worth it, because that's how we prevent malfunctions and breakdowns. You can count on a high level of process reliability.

Here are a few reasons why cam technology is anything but trivial and should be left to the experts.

- Small series: cams and cam gears are often special solutions in small quantities. That requires specialist knowledge about their design and production.

- High power and high speed: cams and cam gears are often used to carry out highly dynamic processes. That means that they have to be precisely calculated. These calculations are complex and should be done by experts.

- Deep inside: because control cams and cam gears are usually installed in the core of the machine, they cannot simply be replaced. Reliability and quality are therefore essential for long-term process reliability and productivity.

- Knowing what the loads are and how to handle them: mechanically highly stressed parts are operating in cams and cam gears. The specifications for production, heat treatment and tolerances are extreme, and the geometries are complex.

- The importance of details: exceptionally long service life and wear resistance can only be achieved if everything is made correctly. So we take great care to rule out even minimal changes in the production process, the alloys, or the hardening.